So I've been having a quick look at Fusion 360 from Autodesk as a program for generating the G-Code for running the CNC Mill. It is possible to write the code by hand, and I have done a little of that for the lathe, and probably will continue to do that for the lathe. However the mill can produce more complex shapes and it will be easy to pass large, complex programs onto it for machining.

Probably most important however is that I can run previews of the toolpaths and the software can calculate the best path using various optimizations or change a tool quickly then re-calculate.

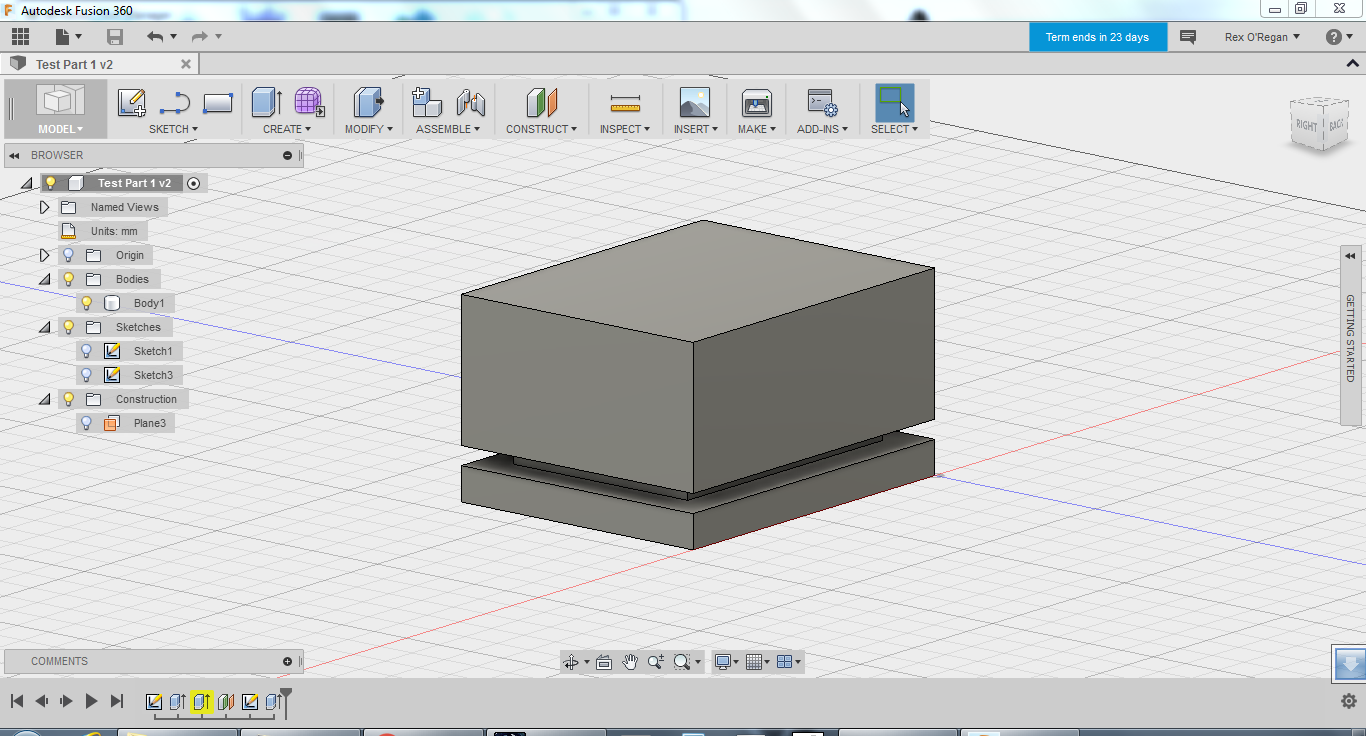

Before I can generate G-Code out of Fusion, I need to be able to draw in it. I am starting by drawing the stock I'm using to make the part out of.

This is a piece of some kind of machineable wax that came with the Mill when it was given to me. It already had the slot in it which I am planning on using to hold down this with. It should be pretty easy on the tools which is good because some of them are pretty blunt.

Here goes. I've had no training on Fusion 360, only other CAD software so I am working mostly from guesswork here. But I did manage to make this part.

I am liking some aspects of this software. It has a number of elements similar to Pro/Desktop which is was I first learnt. Everything can be drawn from constrained sketches which are then transformed. This means that if you've made a mistake in a sketch you can go back to it, fix the mistake and re-calculate all of the parts that are dependent on the sketch. Also being constrained you can make parts that will scale with only one change in dimension.

Keep an eye out for some chips coming soon.

Cheers,

Rex

Comments powered by CComment